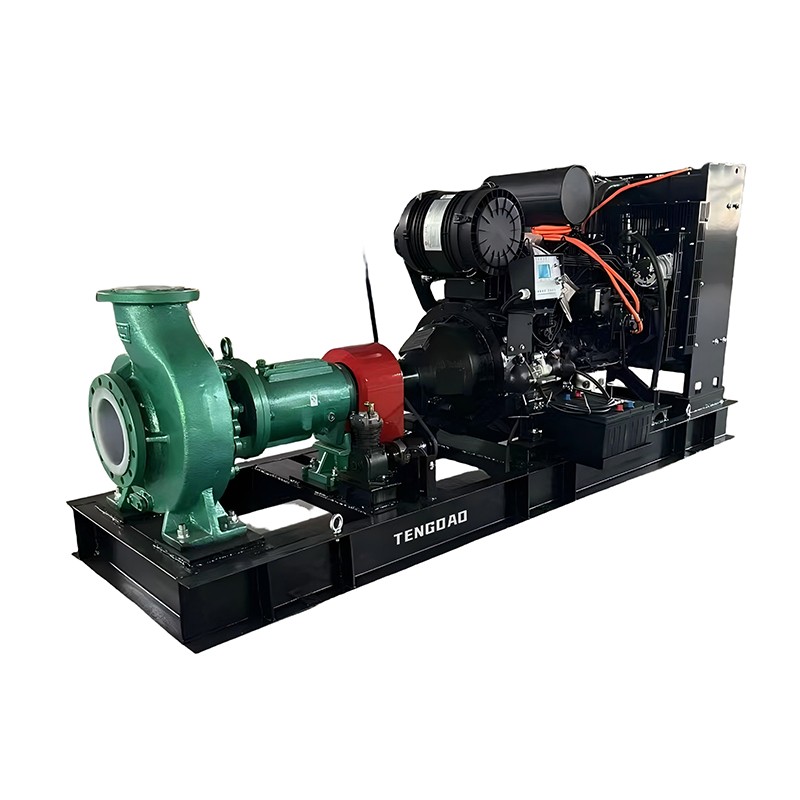

API610 MCZシリーズ ディーゼルエンジン化学ポンプ

API610規格は、産業用途で使用される遠心ポンプのベンチマークとして機能し, 信頼性を保証し, 効率, さまざまな液体の輸送における安全性を確保します. この枠組みの中で, MCZシリーズディーゼルエンジン化学ポンプは、その多用途性と堅牢な設計で際立っています. このタイプのポンプは、特に次の分野で使用されます, 化学製造, 石油化学処理, 製油, パルプ・紙製造, 砂糖製造, その他. 液体輸送の複雑な要求に応えるよう設計されており, MCZシリーズは業界基準に沿った包括的なソリューションを提供します.

Product Overview and Structural Configuration

The MCZ series comprises horizontal, single-stage, single-suction cantilever centrifugal pumps that conform to the DIN24256/ISO2858 standards. Its configuration allows for easy integration into existing systems while ensuring high efficiency. Available in two structural arrangements, OH1 and OH2, the pump is capable of handling both low-temperature and high-temperature liquids. This includes neutral and corrosive fluids, whether they are clean or contain solid particulates, reaffirming its applicability across a wide spectrum of industrial processes.

Some key specifications of the MCZ series pumps include:

流量 (Q): 最大到達可能 2000 メートル³/時.

頭 (H): 最大揚程能力 160 メートル.

作動圧力 (P): 最大作動圧力 2.5 MPa.

作動温度 (T): -80°Cから300°Cまでの動作範囲.

Characteristics: The pump boasts a smooth performance curve, low NPSH (Net Positive Suction Head) values, and high-efficiency ratings even under partial load conditions.

These specifications are critical in ensuring that the MCZ pump can be used efficiently across various industrial environments without compromising operational performance.

Design Features and Advantages

Design Features and AdvantagesThe design of the MCZ series reflects a thoughtful approach to operational efficiency and ease of maintenance, incorporating several advantageous features:

Standardized Dimensions: The dimensions and base plate of the pump are designed according to international standards, enabling seamless replacement of imported pumps and reducing downtime.

Inline Configuration: The pump’s suction and discharge ports are aligned on the same axis, facilitating hassle-free piping and process connections.

Integrated Assembly: The design forms a cohesive assembly of the bearing frame, shaft, 羽根車, and packing gland. This integration allows for maintenance to be conducted without the need to disassemble from existing piping systems, 業務効率の向上.

Pressure Compensation Mechanism: The axial pressure at the seal is managed through balancing holes on the impeller, providing reliable sealing solutions. Users can choose from various sealing options, including soft packing or single and double mechanical seals.

Durable Bearings: The roller bearings are designed for longevity, with a substantial shaft diameter ensuring balance during operation. Certain configurations even feature a double volute design to mitigate radial forces, further contributing to stability.

Versatile Medium Transport Capability

The MCZ series pump’s robust design allows it to transport a multitude of chemical substances across various concentrations and temperatures. The following substances are ideal candidates for transport using this pump:

A range of inorganic and organic acids, including sulfuric acid, nitric acid, hydrochloric acid, and phosphoric acid.

Concentrated alkaline solutions of sodium hydroxide and sodium carbonate at various temperatures.

Various saline solutions.

Liquid petrochemical products, organic compounds, and other corrosive materials.

To accommodate the diverse range of substances handled, our manufacturing facility utilizes a variety of corrosion-resistant materials such as 303, 305, 306, 307, 316, 316L, 904, 904L, 804, ECR alloy, Hastelloy, CD-4MnCu, and titanium alloys. The selection of materials aligns with the requirements of the specific media being conveyed, ensuring both safety and operational longevity.

MCZシリーズのディーゼルエンジン化学ポンプは、化学加工産業の厳しい要求に応える現代の技術の卓越性を示しています。. 腐食性および中性のさまざまな液体を効率的に輸送できる能力, 堅牢な設計特長と国際規格への準拠と相まって, 産業用途における重要なコンポーネントとしての役割を強調しています。. 産業が進化し続け、流体輸送の信頼性の高いソリューションを求める中で、, MCZシリーズはポンプ製造における革新と品質へのコミットメントの証となります。. 顧客には注文時に輸送予定の液体に関する詳細情報の提供を推奨します, 各用途に最適な性能と材料選定を確保するために。.

パンプス,発電 機,灯台,油圧ステーション-TENGDAO

パンプス,発電 機,灯台,油圧ステーション-TENGDAO