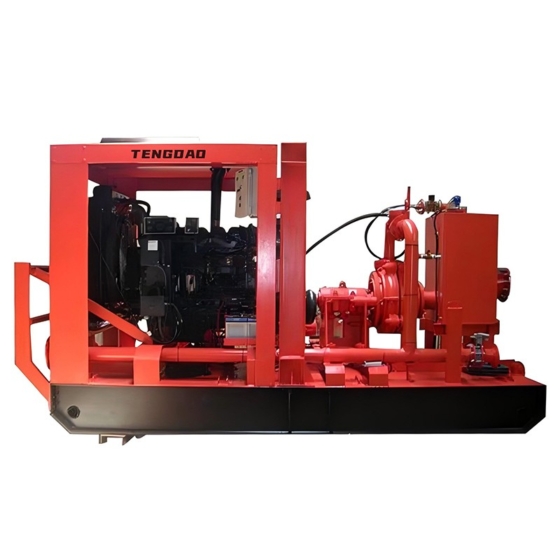

엔진 구동 고형 입자 진공 보조 탈수 원심 슬러리 펌프: 개요

기술 사양

– **유량:** 100 받는 사람 15,000 m³/시간

– **머리:** 20 받는 사람 250 m

– **적용 환경:** 산업용 광산 지역, 석탄, 발전 분야

– **호환 가능한 엔진 브랜드:** 커 민 스, 퍼 킨 스, 도이츠, 위차이, 시차이, 웨이차이(威洋)

– **장치 유형:** 스키드 장착, 이동형, 및 플로팅

제품 개요

엔진 구동 고형 입자 진공 보조 탈수 펌프는 업계에서 새로운 기준을 설정하는 다목적 수펌프입니다. 경량화 및 사용자 친화적으로 설계되었으며, 저수 및 고수 두대 양쪽 모두에서 효율적인 작동이 가능합니다. This pump is tailored to meet the growing needs of global mining enterprises as mining operations extend from shallow to deep pits.

Constructed from CA6NM material, this pump offers superior durability and wear resistance. The design features wider flow passages to accommodate larger particles, ensuring that it can handle tough conditions with ease. The vacuum assistance, at a capacity of 1.3 m³/min, provides rapid water intake, while the diesel engine’s pump coupling employs a SAE J620 direct connection with internal flexibility for high transmission efficiency. The instrument system includes waterproofing, loss-of-water protection, bearing temperature monitoring, cavitation protection, and multiple safeguards for the engine, ensuring stable and reliable operation without complex procedures.

Constructed from CA6NM material, this pump offers superior durability and wear resistance. The design features wider flow passages to accommodate larger particles, ensuring that it can handle tough conditions with ease. The vacuum assistance, at a capacity of 1.3 m³/min, provides rapid water intake, while the diesel engine’s pump coupling employs a SAE J620 direct connection with internal flexibility for high transmission efficiency. The instrument system includes waterproofing, loss-of-water protection, bearing temperature monitoring, cavitation protection, and multiple safeguards for the engine, ensuring stable and reliable operation without complex procedures.제품 소개

The engine-driven solid particle vacuum-assisted dewatering centrifugal slurry pump is produced using advanced international technology and is available in three main series: MH, HH, and M. Each series may share many common characteristics while catering to different operational requirements.

**M, MH, and HH Series**

These series consist of cantilevered horizontal centrifugal pumps. The shaft seals can be either packing seals or centrifugal seals, and the pump outlet can be adjusted to meet specific needs, with each adjustment providing a 45° angle change. These cantilevered centrifugal slurry pumps are ideal for transporting high-concentration and corrosive slurries across various industries, including metallurgy, 광업, coal ash, power generation, and building materials.

**M 및 MH 시리즈**

HH 시리즈와 달리, 펌프 케이싱, 임 펠 러, M 및 MH 시리즈의 라이너는 내마모성 금속 또는 고무로 만들어집니다.. 특히, 라이너 이 펌프는 교체 가능, 수명과 효율성을 향상시킵니다..

이 펌프는 교체 가능, 수명과 효율성을 향상시킵니다..

이 펌프는 교체 가능, 수명과 효율성을 향상시킵니다..

이 펌프는 교체 가능, 수명과 효율성을 향상시킵니다..응용 프로그램

이 펌프의 다양성은 다양한 응용 분야로 확장됩니다., 포함:

– **알칼리 및 무기염:** 석회 슬러리와 같은, 소금 슬러리, 및 탄화물 슬래그.

– **비철금속 야금:** 알루미늄에서 슬러리 처리용, 구리, 바나듐, 및 아연.

– **석유화학 산업:** 모래가 함유된 원유 취급.

– **제지:** 석회 슬러리 활용.

– **발효:** 슬러리 발효 공정 관리.

– **발전 및 환경 보호:** 석탄재 처리, 석고 슬러리, 등.

특징 및 장점

1. **완전 자동 작동:** 펌프는 수동 개입 없이 자동으로 물을 끌어올 수 있습니다, 작업 효율성 향상.

2. **풋 밸브 필요 없음:** 적절한 작동을 위해 풋 밸브가 필요한 기존 펌프와 달리, 이 탈수 펌프는 그 필요성을 없애고, 설치 간소화 및 비용 절감.

3. **통합 진공 펌프:** 소형 유닛으로 설계, 이 진공 펌프는 고장 가능성을 최소화하며, 시스템 신뢰성을 높인다.

3. **통합 진공 펌프:** 소형 유닛으로 설계, 이 진공 펌프는 고장 가능성을 최소화하며, 시스템 신뢰성을 높인다.4. **오일 윤활 기계식 씰:** 기계적 씰은 오일 윤활, 물 없이 24시간 연속 운전 가능, 내구성과 적응력을 크게 향상시킴.

5. **배수 밸브 설계:** 배수 밸브는 펌프 내 액체를 완전히 제거할 수 있게 해주며, 불쾌한 냄새와 박테리아 증식을 방지한다.

6. **고온 커플링:** 펌프와 엔진 간 연결부는 완전 고무 고온 커플링을 사용하여 안정적이고 신뢰할 수 있는 동력 전달을 보장한다.

7. **조절 가능한 각도 핫딥 아연도금 퀵 커넥트:** 펌프 입구 및 출구의 퀵 커넥트 피팅은 조절 가능하여, 배관 구성 및 설치를 더욱 용이하게 함.

8. **구형 견인봉 및 토크 진동 완화:** 구형 견인봉은 안정적인 지지와 안내를 제공하며, 토크 진동 완화 장치는 운전 중 진동과 소음을 최소화함.

결론적으로, 엔진 구동 고형물 진공 보조 탈수 원심 슬러리 펌프는 다양한 산업 응용을 위해 설계된 정교하고 견고한 솔루션임. 혁신적인 기능은 효율적인 운전, 장수명, 및 열악한 작업 환경에 대한 적응성을 보장함, 현대 광산 및 산업 작업에 필수적인 도구임.

펌프,발전기,등대,유압 스테이션 - TENGDAO

펌프,발전기,등대,유압 스테이션 - TENGDAO